Go to the new and full English version of the site

K2150 sensor is able to detect movements of humans, vehicle or other mechanisms on the area up to 3 000 square meters (32 000 sq feet).

The sensor can be used in:

– lighting control system

– building management system, industrial and urban territories

– IoT systems, Smart manufacturing, Smart street and Smart City

– as a tool of “machine vision” with an angle of 180 degrees and the range up to 80m

Since July 2018 this product is included in the portfolio of “1000 most promising solutions” the World Alliance for Efficient Solutions, established by the Solar Impulse Foundation.https://solarimpulse.com/world-alliance

Go to the new and full English version of the site

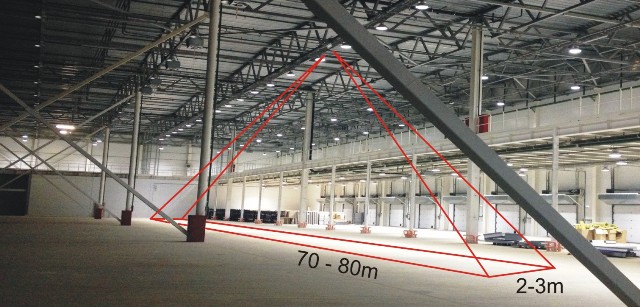

K2150 sensor in warehouses lighting control systems

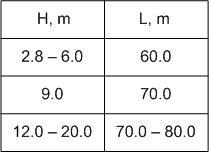

The К2150 occupancy detector for lights control is designed to be installed on a height from 3 to 30m. It can also be installed on a wall, 1.5-2 m from the floor, for controlling the lights of warehouses picking and loading areas, various production areas, car parks, urban streets, squares, and so on, with a large operation zone up to 3000 sq m (at most 160″ 40х70 m).

The sensor traces the movement of a person or motor vehicles and transmits the control signal to the lighting system.

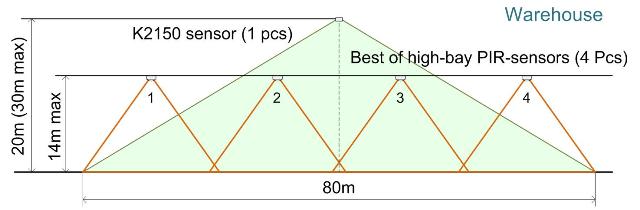

K2150 can substitute 3-4 common used similar PIR-sensors manufactured by another companies. It hasn’t competitors placed on height more 14 m and in freezing warehouses.

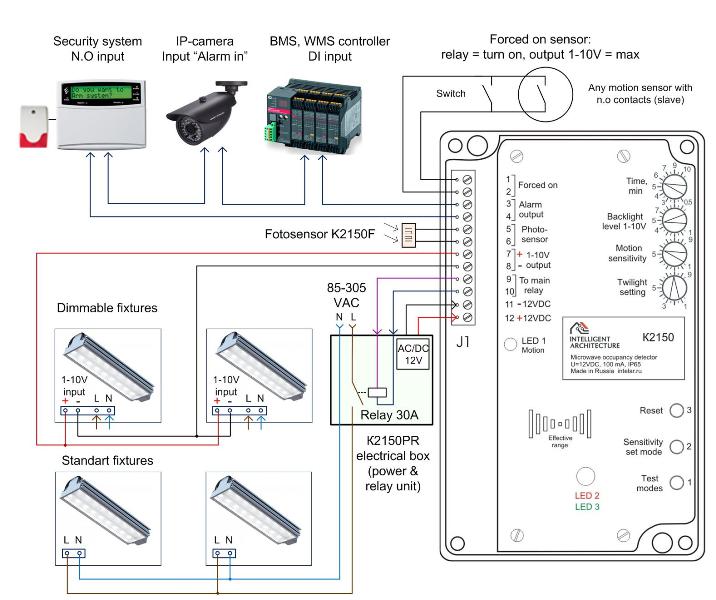

К2150 is a three-in-one sensor: one sensor and three outputs

1. the relay 30А output is for controlling regular lamps (if a movement does not occur, then the lamps are off, if it does, then they are on);

2. the 1-10V output is for adjusting a light flux gradually within 2-100 % (if a movement does not occur, then the lamps operate at the economical mode set by the installer, from 2 % to 100 % of the light flux, if it does, then they gradually, in 2 seconds, switch to the 100 % light flux mode). For your information: at the 5 % light flux mode, the energy consumption of an LED lamp decreases by 12 times, of a luminescent one by 6 times!

3. the special output is for connecting the sensor to a security alarm system or to IP-cameras. By using this output, the sensor can also be connected to an automated warehouse control system for tracing and highlighting bays with a high load (a forklift drives through too often) and underused bays (a forklift drives through seldom) and subsequently optimizing the distribution of items. The sensor may optionally be supplied with: DALI, KNX, LoRa, Sigfox, NB-IoT, Wi-Fi, BLE 5.0, … modules and a long-range radio channel 868 mHz (up to 15 km).

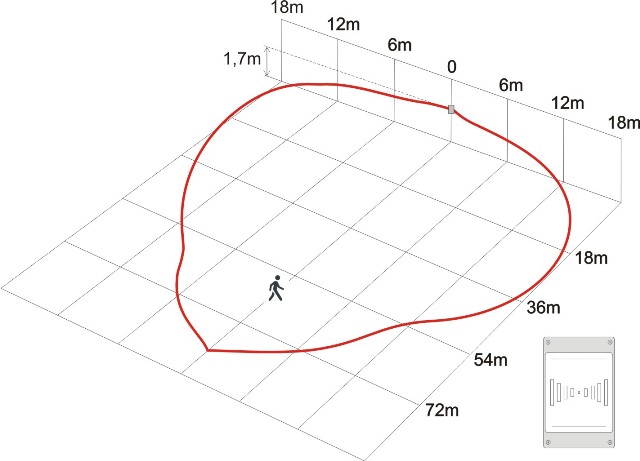

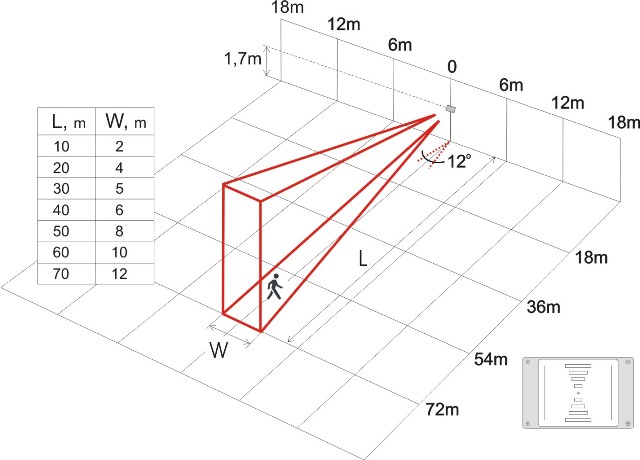

К2150 sensor’s sensitive area

The width of the К2150 sensor’s sensitive area depending on the installation height H (person’s movement tracing!)

The К2150 sensor’s sensitive area when vertically installed on a wall

The К2150 sensor’s sensitive area when horizontally installed on a wall

How the К2150 sensor works and how it is different from an infrared motion sensor (PIR)

The К2150 sensor’s functional principle is based on radiating an electromagnetic field to the surrounding area and registering its changes caused by its reflection from the objects moving in the sensor’s sensitive area.

Nowadays, the main competitors are generally German ceiling passive infrared motion sensors with the installation height of 10-12 m and the sensitive area width of about 30 m.

At the same time, infrared motion sensors have a significant drawback, namely, they trace not the movement itself but the difference between the temperatures of the moving object and the surrounding area. That is why infrared motion sensors miss the movement if, for example, the forklift has cooled down to the ambient temperature, and the driver’s cabin is covered by plexiglass or the driver is wearing warm coveralls.

The same problem occurs in warehouses in hot weather when the air gets warmed up to 34-36 °C, and the sensors cease to trace a person’s movement.

Another feature of infrared sensors is that they trace the movement at certain points of its area, and the distance between those points can amount to several meters; therefore a few of them must be installed for one bay with the turn-off delay of about 10 min, which significantly reduces their effectiveness and pay-off period (the bay is already empty, but the lights will work for 10 more min).

The К2150 sensor does not have these drawbacks. At the place where four infrared motion sensors must be installed, one К2150 sensor with the turn-off delay of about 0.5 min is sufficient because the sensor traces each step of the person, that is, it has a high sensitivity level.

Sensor size is 125х80х40 mm. All weather execution, IP65, IP67.

К2150 sensor applications

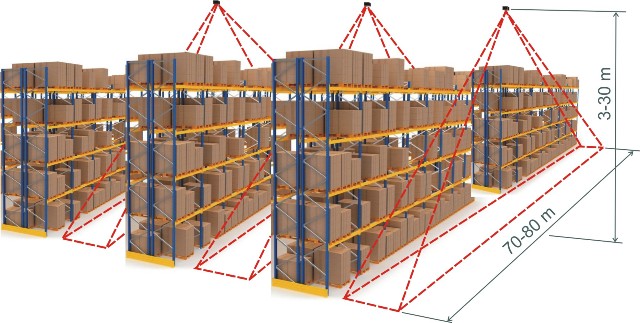

1. Warehouses with the height from 3 m to 30 m and higher (installation on the ceiling of racking lanes or on the wall of picking zones)

2. Indoor and outdoor car parks (installation on the wall); the wide sensitive area, approximately 40 x 70 m

3. Server rooms and DPCs (the sensitive area width between cabinets is about 70 m at the 2.8-5 m installation height)

4. Any production facilities, including those with thermal radiation sources in which infrared motion sensors will not work (installation on the ceiling or walls)

5. As a traffic intensity control sensor, including transport + pedestrians for the Smart City and Smart Street systems

6. As a motion sensor for controlling street light at parks, squares, and car parks at shopping molls, including ones complete with К2304 1-10V autonomous self-learning light dimmers

7. As a traffic intensity measuring sensor for street light control systems, including ones able to count the number of vehicles

8. As a intruder detection sensor for guarding a protected area’s perimeter and volume, including ones with an additional function of controlling the area lights by movement.

К2150 sensor’s cost effectiveness (using the example of a warehouse)

The object is an actual warehouse with the 72х78 m area, 17 m height, and shelf storage of items. The length of the shelves is 68 m. The forklift drives through the bay every 7 min and stays there for about 1 min. 150 W LED lamps without a dimming function, 216 pcs. The number of bays is 18; the number of lamps per bay is 12. The lights duty cycle is 24 hours per day.

Energy consumption without automation is 283,824 kWh per year.

Energy consumption with automation (3 emergency lamps, 9 lamps that get turned off by the sensor) is 97,567 kWh per year.

Savings: 283,824 – 97,567 = 186,257 kWh per year or 186,257 х 0,15 € = 27,938 € per year.

The modernization cost, including the installation cost, is approximately 24,000 €.

The pay-off period: 24,000/27,938 = 0.8 years.

If food is stored in the warehouse, that is, the warehouse is artificially cooled, then it is necessary to consider the following. Nowadays, even the best LEDs use only 20 % of the energy for light emission and 80 % for heat generation. Therefore, the 150 W lamp is not only a light source but also a constantly working 120 W heater (150 W x 0.8 = 120 W)!

_

Thus, the total heat generation of the lamps in such warehouse is 216 pcs. x 0.12 kW = 25.9 kW, and the warehouse cooling system must constantly compensate for this heat generation! Using motion sensors at such facilities will give additional, significant savings, and the pay-off period of the automated light system will be reduced.

When installed in a warehouse, one Sensor replaces 3-4 PIR-sensors and saves 150 000 kWh over a 15-year life cycle (if a warehouse is open around the clock). One sensor in a life cycle will reduce CO2 emissions to the atmosphere by 60 tons.

_

We recommend that you install dimming lamps in warehouses and parkings (1-10V protocol). Their price is almost compatible to the price of a standard lamp today! The dimming function will allow to create a light environment comfortable to eyes without abrupt changes in illumination when the automatics operate, to avoid commutation network loads, and to extend the lifetime of the lamps.

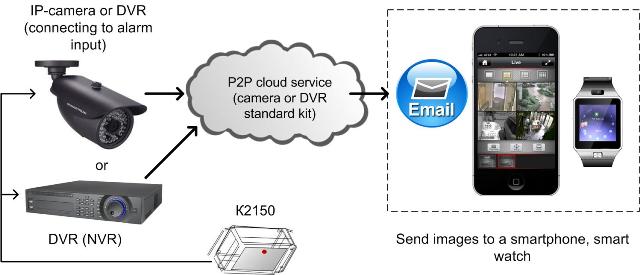

К2150 sensor alarm output connection

The sensor alarm output (solid-state relay) functions in the same way as the alarm output of any professional motion sensor for a security alarm system, but it is normally open on standby, and it closes for 1 sec after detecting a movement. Delay time and photosensor settings and positive engagement do not affect its operation, that is, this channel is completely independent.

The alarm output connection to a security alarm station is the same as the connection of any other sensor to an IP-camera and DVR/NVR, i.e., to the “Alarm In” input.

Example.

When connecting the alarm output to the CCTV system of, for example, a warehouse, you can implement the following script. The warehouse operates from 07:00 am to 08:00 pm. The IP-camera or DVR/NVR digital video recorder menu has a registered entry which says that when inputs Nos. 1…N trace an alarm signal within the period from 08:15 pm to 06:45 am on working days and 24 hours a day at weekends, the video image, accompanied by a sound signal, goes from multiplex to full-screen at the guard post, and the alarm camera photos get sent to the company owner’s or other agent’s e-mail and smartphone. This will allow to reveal thievery of goods, including cases when the warehouse security service is involved.

Go to the new and full English version of the site

OEM is welcome!