Why warehouses?

According to Forbes, warehouses have the highest profitability. In the next 10–15 years demand for offline shops will start decreasing, yet demand for warehouses is going to increase.

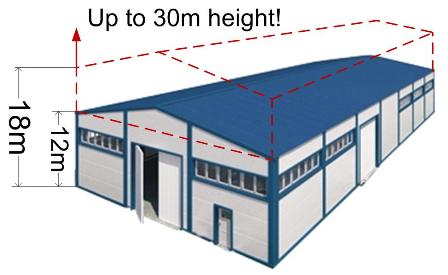

In the world there is a trend for construction of high warehouses, but it has one problem.

In high warehouses the power of lighting increases essentially, because of that, implementation of “light for demand” principles can be extremely beneficial.

Go to the new and full English version of the site

So what is the issue?

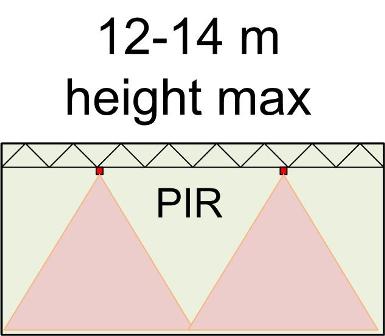

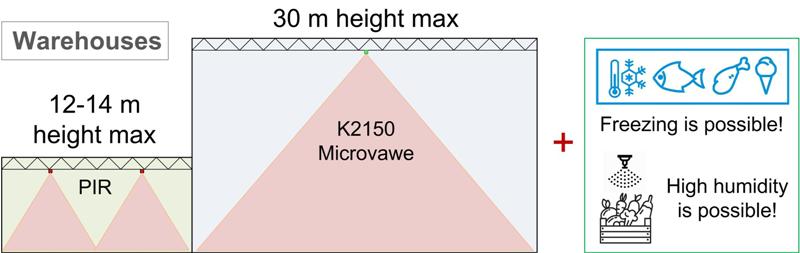

All existing motion sensors (usually PIR) can operate only at a height of 14m or less, only at positive temperature and with dry air.

Therefore higher warehouses and freezer warehouses are left without automatization!

Our sensor K2150 solves these problems!

… and offers more options!

Sensor efficiency

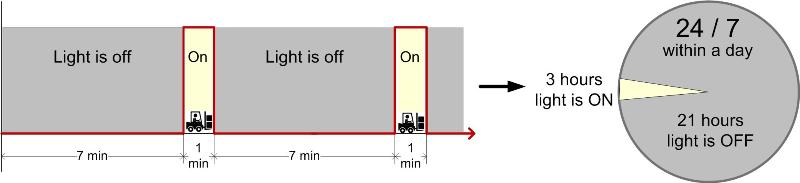

In the picture you can see the real result of traffic measurements in dairy warehouse.

If the forklift enters the alley every 7 minutes and works there for 1 minute, then during the day the lighting in the alley is used only 3 hours and 21 hours it isn’t necessary and can be turned off or its power can be smoothly reduced to 10%.

– Energy saving is up to 80%!

– The payback period is approximately 1 year

– One sensor saves up to 10 000 kW/hour electric power per year (24/7)

– One sensor in a 15-year life cycle will save about 150 000 kW*hour and decrease emissions of СО2 in atmosphere on 60 tones

Energy efficiency of 70-80% is usual, not unique for warehouses.

The usual payback period of 1 year indicates a very good dependence between the price of our device and its efficiency.

The best result we had at the customs warehouse in the Smolensk region. The payback period there was 6.5 months.

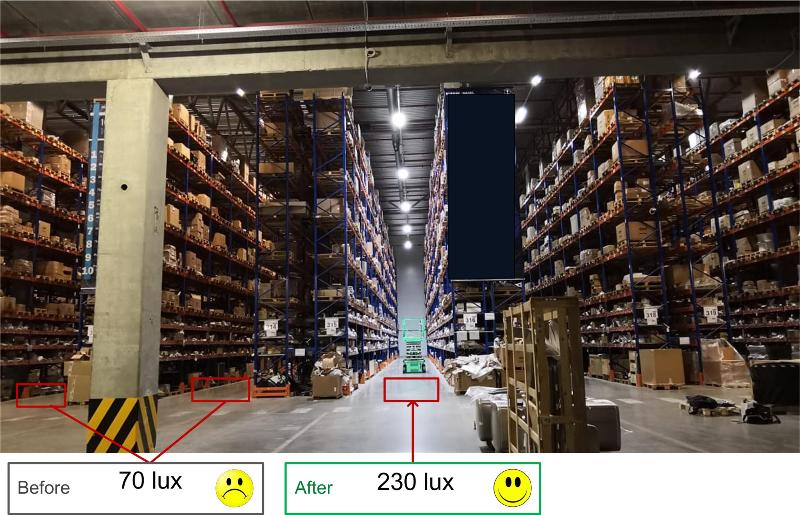

An interesting experiment in the warehouse of a well-known logistics company

In one warehouses alley installed 14 pcs fluorescent fixtures with a capacity of 80W. But the illumination level at the floor is only 70 Lux. Our partner’s installation company has replaced them with 6 led fixtures with a capacity of 121W and our motion sensor in one alley.

They also installed electric meters on two lines and got this result.

Real installation cases of the sensor K2150 in warehouses:

– a cooling warehouse with a height of 17.5m (one sensor in the alleys 65m long) of a well-known producer of dairy products, Moscow

– a warehouse with a height of 18m (one sensor in the alleys 80m long!) of the largest distributor of medicines in Russia. Moscow Region

– several warehouses with a height of 17.5 to 19m (one sensor in the alleys 65m and 80m long) of the largest manufacturer and distributor of medicines in Russia. Moscow and Moscow Region

– a warehouse with a height of 10m (one sensor in the alleys 65m long) of the regional retailer, Tatarstan

– a warehouse with a height of 11m (one sensor in the alleys 45m long) of the famous world manufacturer of sports goods and equipment, Moscow Region

– warehouses with harsh operating conditions of the largest Russian retailer, the distribution center in the Yaroslavl region. Cooling warehouses, freezing warehouses, and warehouses with a high-pressure sprinkler system (vegetables, fruits) with a height of 9m (one sensor in the alleys 40-50m long) were automated. In some warehouses, mounted on a wall. After a year of operation, the K2150 sensor is included in the design of a similar distribution center in Kazan

– a warehouse with a height of 12m (one sensor in the alleys 50m long) of the famous manufacturer of instant noodles, Moscow Region

– a warehouse with a height of 12m (one sensor in the alleys 80 m long!) of the famous brewing company, Moscow

– customs warehouse with a height of 8m, Smolensk region. Electric meters were installed to predict the payback period of investments. At tariffs of 7.30 rubles / kWh, the payback period was 6.5 months!

– -28 degrees Celsius freezer warehouse with a height of 12m from the world-famous ice cream manufacturer, Novosibirsk. After extensive testing of sensors, they were recommended for use in a comprehensive modernization of the lighting system of the company’s facilities

– a warehouse with a height of 6m (one sensor in the alleys 60 m long) of the well-known Russian manufacturer of roofing systems, Voronezh region.

Why Intelar?

We apply much more progressive microwave technology instead of passive infrared one

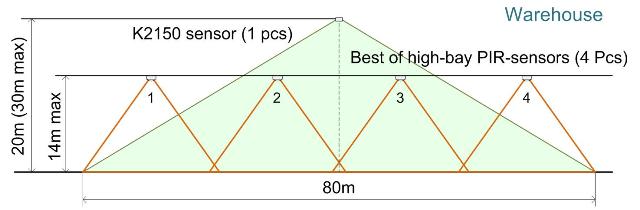

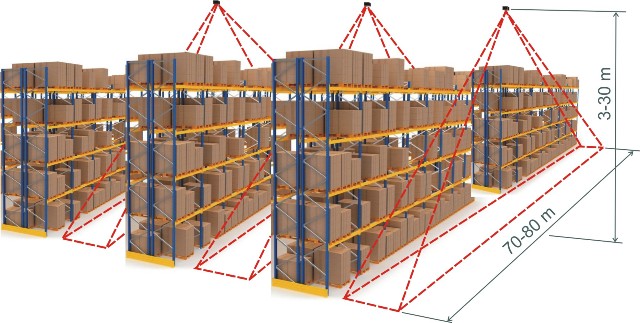

One sensor controls 80 m of warehouses alley and replaces 3-4 High-bay PIR sensors of the best worldwide manufacturers

K2150 is the only sensor that can operate on the height from 3 to 30 meters

You can build high warehouses and our sensor will help you in saving huge amount of energy

High reliability Automotive series microcontroller inside